Accepting the gift

WAM Engineering's brass corrective shims optimize geometry while imparting stunning sonic benefits.

Don’t ever let being a physics flunky get in the way of describing a good thing. That’s a solid headline for this quick meditation on a piece of brass.

Ok, before I get into that, allow me to introduce myself. I am a friend of Michael Fremer’s, who some of you have read about in Stereophile. I struggled with a very expensive malfunctioning arm on my turntable and all the attendant problems that it inflicted on my even more expensive Lyra cartridge. Michael wrote about my saga with admirable journalistic integrity, and I will say for the record that both companies handled this situation with professionalism and swift action. But it doesn’t hurt having friends in proverbial high places to help escalate fixes to expensive problems. So, this little meandering riff is about just that.

Years ago when I first got the system that I still enjoy today, the person setting it up struggled with setting the antiskating on my Kuzma arm. Knowing what I do now, I should have allowed my murmuring concern to be a full-throated yell to stop and take action. But, I pushed forward and after not too long I noticed that my cantilever developed a skewed angle that might have been beneficial in other contexts, but it certainly didn’t benefit my audio playback. That’ll be enough prurience for today.

Enter J.R. of WAM engineering. I could go on and on about him, but let’s just say that he is extremely knowledgeable, measured, and he’s doing a job for which he was made. As a teacher, I understand the level of patience that he musters for his clients. Having restraint with children is essential and not so difficult to conjure but summoning this for grown children is another matter entirely.

After using Mr. Fremer’s personal Wally Skater (I have since bought my own- and so should you), we determined that there were bearing issues in my 4 Point 9 arm. So, off it went. And my cartridge went back to Lyra. Both came back a few months later in new condition and I enjoyed years of listening. Thanks to all involved.

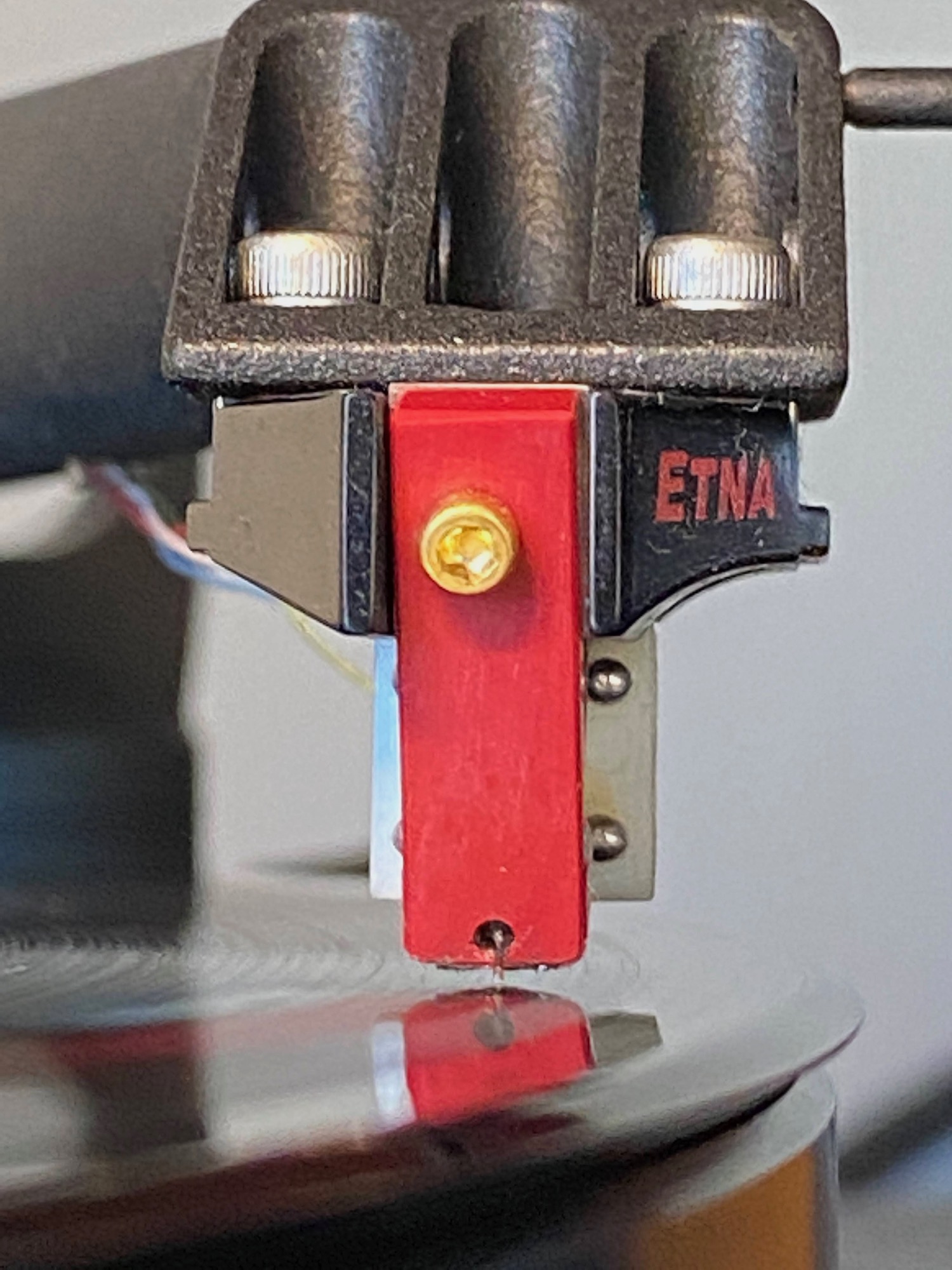

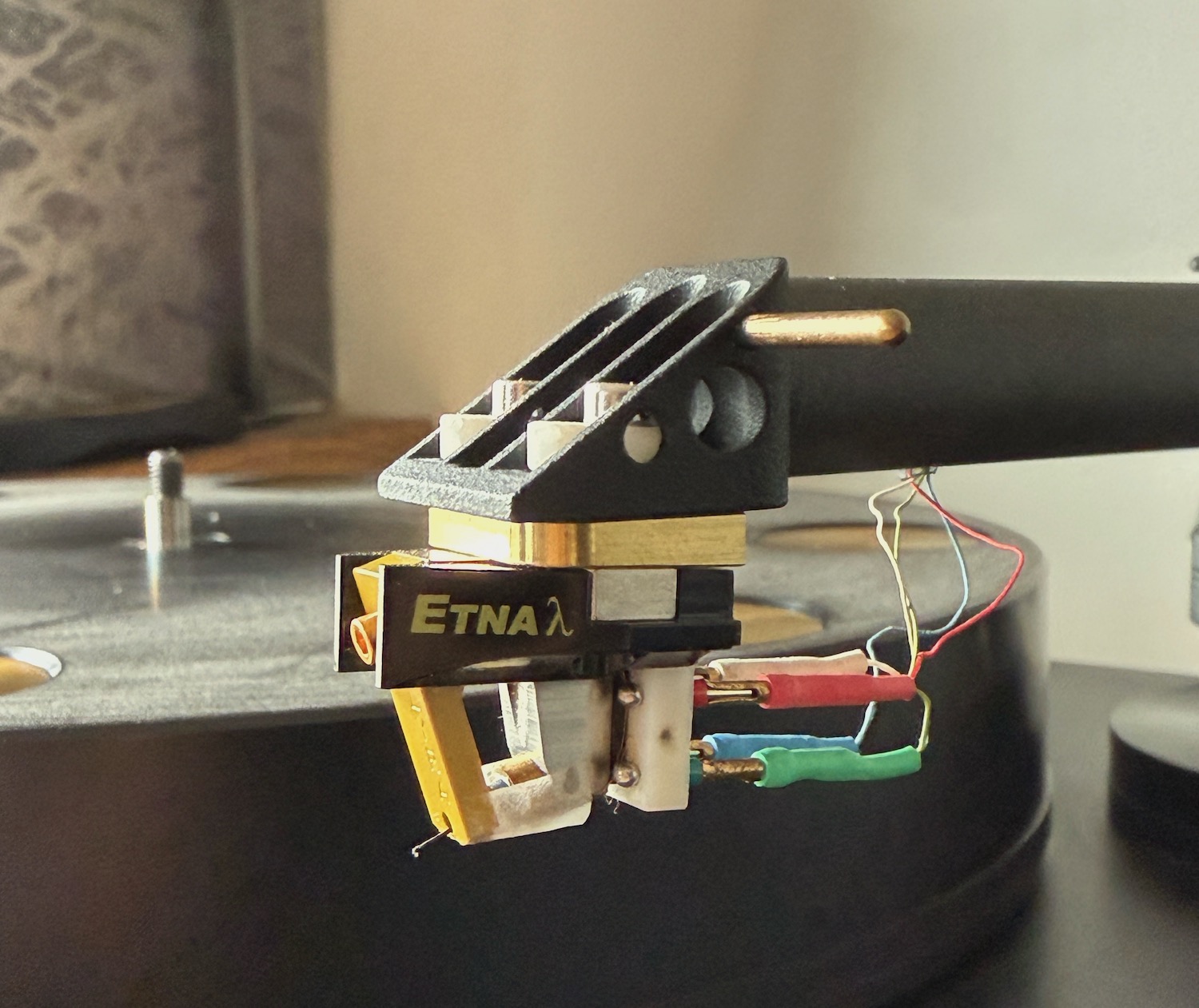

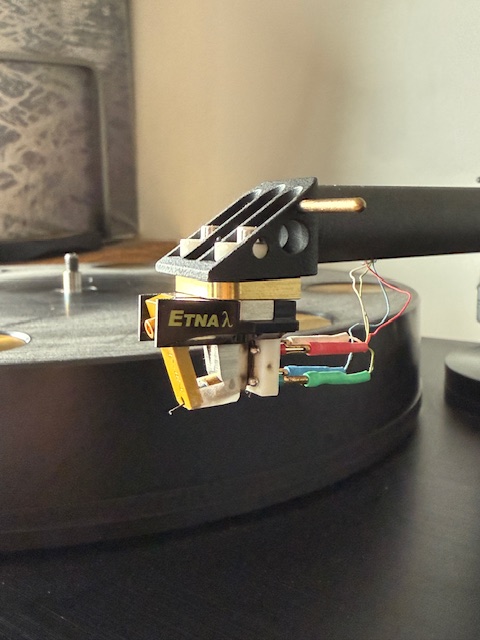

But, when it came time to step up to the new Lyra Etna Lambda, I decided to take a different approach. There has been much written about the manufacturing tolerances of audio equipment- we are talking about skewed cantlivers, crooked styli and other such horrors. One would think these issues would not be a thing in high end audio, but they are. And, they certainly sting more with the price paid and no one around to tell you that you aren't crazy and that this thing just may be…broken.

So, I sent my brand new Lambda to J.R. for his cartridge analysis service. I figured he’d be able to aid me in deciding whether my Etna was a keeper. And, it turned out that it was! However, there were tolerances that could be tightened up with shims. So I decided to go for it and have been rewarded with the best listening experience of my life. Best of all, with J.R.’s shims, there is no need to use a microscope to adjust SRA/VTA, and you don’t need a Fozgometer to adjust azimuth. Just make sure the arm is perfectly parallel to the record in both planes (best to use the Wally Reference tool for this), set tracking force and anti-skating and enjoy.

Yet, curiosity doesn’t always result in a dead cat, so I did wonder (over a year later) what JR’s upgraded brass shims would do to my system’s golden sounds. Initially, I was put off by the extra couple hundred dollars and went with his standard shims. But, I have experienced the benefits of adding mass to guitar necks and bridge pins over my years of playing and collecting vintage instruments. This curiosity resulted in countless hours researching the effects of a higher mass tonearm. The logic was certainly there, as was my desire to experiment. So, off my cartridge went to California for J.R.’s Kuzma mounting service. I sent him my headshell, and all he did was change the shims to brass. The brass adds an additional 5 grams of mass to the headshell over the additional 1.2 grams of mass that the resin shims add to a cartridge alone. So that’s a significant number. I reset tracking force and was ready to listen.

“To say that my wife and I were stunned (yes, I’m an audiophile who actually listens with his partner) would be an understatement. There was such a sense of blackness of background: Instruments hung in space with such weight and dimensions. There was far more thrust to the bass, but it was more tightly controlled. The high end was extended and cymbals sounded like actual cymbals in a live room. My center image was tighter and more lifelike. And here comes the classic, unsatisfying audiophile observation: Everything just sounded bigger and better. J.R. commented that “basically we are making it tougher for the groove content to modulate the headshell, thereby lowering the noise floor.” The end result was the same Lyra with identical mounting angles but with more mass. And the brass imparts a salutary influence on the mechanical impedance between the headshell and cartridge. J.R. did mention: “A cautionary note: The devil is firmly ensconced in the details: adding mass without strict adherence to standards of rigidity and placement can cause things to sound worse, not better. WHERE you add mass, WHAT mass you add and HOW you affix that mass is critical to the results.”

So, do I have a perfect understanding of what brought such a massive change to my playback performance? Well, that’s a big no. A sense? Yes, but it doesn’t really matter to this listener. It has never sounded so good, and I’ve learned to stop questioning things that truly work. Accept a gift. Sometimes it’s just time to say thank you and enjoy my records.

.png)