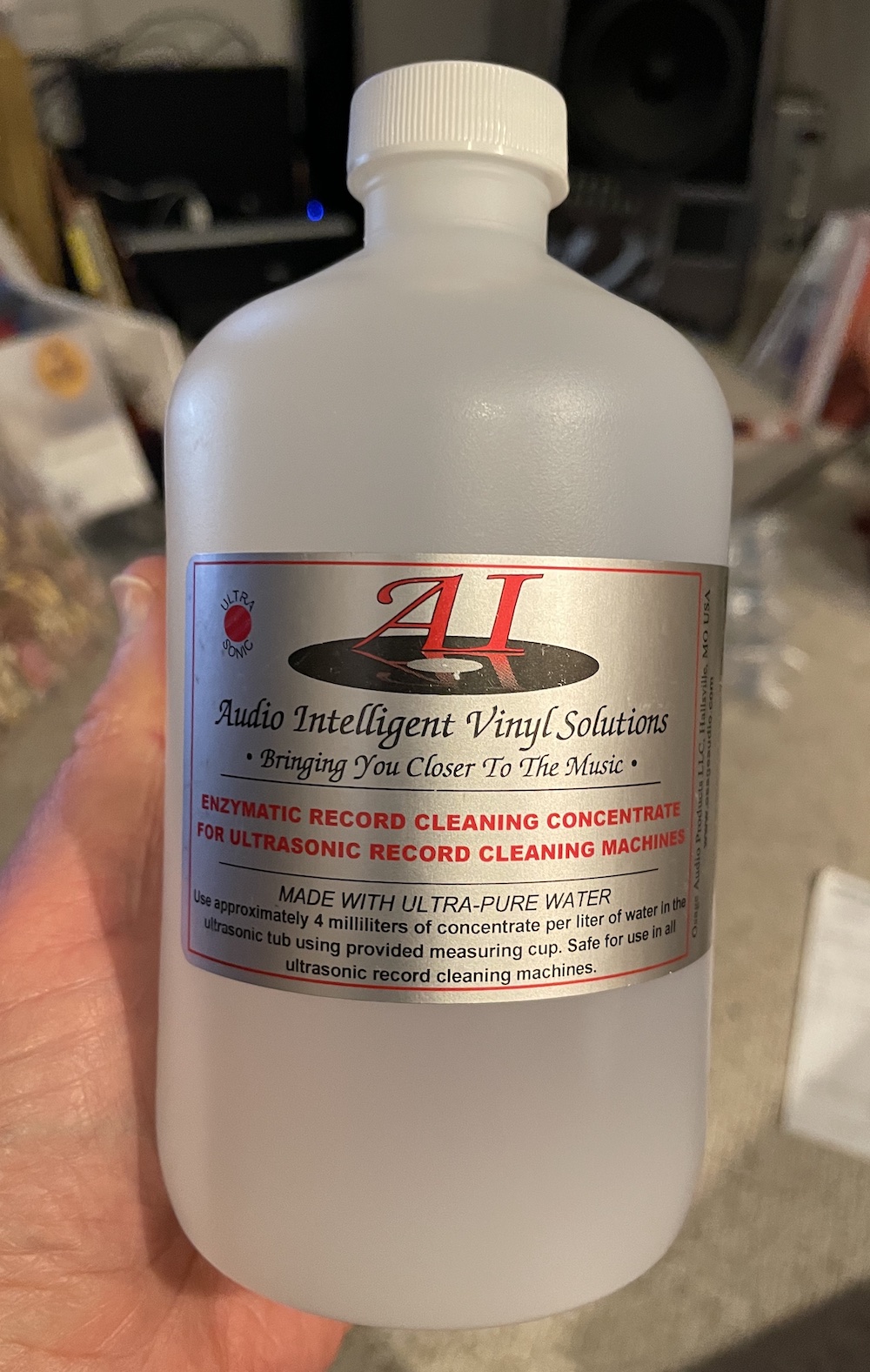

Audio Intelligent Enzymatic Record Cleaning Concentrate For "Ultrasonic" Cleaning Machines

brings down the fluid cost but may void your Audio Deske warranty

Owners of the Audio Deske record cleaning machine know it's convenient and does a good job cleaning records. They also know that the Audio Deske cleaning fluid is costly: $33 for a single small bottle of detergent good for cleaning approximately 150 records, depending upon how clean or dirty they are going into the machine.

Because of the cost, it's tempting to use the tank up to the 150 record limit even if you think it's better to change it more frequently. Audio Intelligent has a solution, literally with its enzymatic concentrate specifically made for use in "ultrasonic" machines. 4 milliliters per liter of water in the ultrasonic tub.

The non-foaming fluid costs $34 for 16 ounces and $50 for 32 ounces. It comes with a handy measuring cup. I've used it in the Audio Deske machine and it seemed to work as well as the Audio Deske fluid while costing way less.

However, there are a few things to keep in mind. First, I believe Audio Deske will void your warranty if you use anything but their fluid. If your machine breaks under warranty how would they know what fluid you were using (unless you tell them)? I have no idea. So that's something not worth worrying about. Once your machine is out of warranty, no problem at all and you'll both save money and can more often change the fluid in the tank, which is a good idea! Why not err on the side of caution especially since the foam "filter" in the Audio Deske is pretty much useless other than for gross particulate matter.

However, there's another issue and that is, while the Audio Deske is an ultrasonic" record cleaning machine, it is not a cavitation-based one, though for a long time I though it was. It does have a transducer that excites the water with ultrasonic bubbles (it's the out of focus disc at the tank bottom on the right side in the below photo), but as is pointed out in the comments, ultrasonic bubbles do not produce cavitation. Still, the Audiodeske cleans well and is far more convenient than a velvet lips vacuum type record cleaning machine.

If you have an Audio Deske, run it without a record and watch the water above the disc. There should be a swirling "vortex" directly above it. That's the action produced by the device, but that's not cavitation. In fact, based on the definition of "cavitation" you do not need a detergent to clean records, or jewelry or anything! Do you know what cavitation actually is and how it works? I don't think I've seen it defined in any review of cavitation-based (or alleged cavitation based) record cleaning machines. What cavitation is, how it works and how it cleans records will be part of an upcoming video on the TrackingAngle YouTube channel.

If you have an Audio Deske, run it without a record and watch the water above the disc. There should be a swirling "vortex" directly above it. That's the action produced by the device, but that's not cavitation. In fact, based on the definition of "cavitation" you do not need a detergent to clean records, or jewelry or anything! Do you know what cavitation actually is and how it works? I don't think I've seen it defined in any review of cavitation-based (or alleged cavitation based) record cleaning machines. What cavitation is, how it works and how it cleans records will be part of an upcoming video on the TrackingAngle YouTube channel.

One thing to keep in mind when using an Audio Deske or other machines that fan dry records: whatever detergent residue that remains on the record once the fluid has been pumped out of the tank and the fan begins to blow, will dry onto the record. At the very least, if you do use an Audio Deske, you should give the record a post-cleaning "spritz" with distilled water and dry the record with a microfiber cloth.

While using an enzymatic cleaning fluid like this one from Audio Intelligent in a true cavitation-based machine might not do any harm, (as long as you follow up with a "spritz"), I don't see how it does any good. Cavitation alone is far more effective than any detergent, though for vacuum and string type machines (and the Audio Deske) a detergent/surface tension release agent is certainly a good idea.

If you are wondering about the Kirmuss "restoration" method that uses cavitation and a propane-base fluid, it's not there as either a detergent or a surface tension breaker. Its only job is to change the charge of the record so it's opposite of the water's charge since opposites attract and "likes" repel. But that's for the cavitation video.

Conclusion: if you use an Audio Deske and are willing to chance voiding the warranty, my experience with the Audio Intelligent fluid is that it's as useful as the Audio Deske fluid and is far less costly meaning you'll be encouraged to change the tank water more often and that's a good thing!

It would also be a good thing to know what are the ingredients and whether they are child and pet friendly in case of ingestion etc.

Specifications

N/A

Manufacturer Information

Osage Audio Products, LLC ∙

P.O. Box 232 ∙ Hallsville, MO 65255

573-696-3551

www.osageaudio.com

info@audiointelligent.com

.png)