iSonic 6.1 PRO 48kHz "Ultrasonic" Record Cleaning Machine

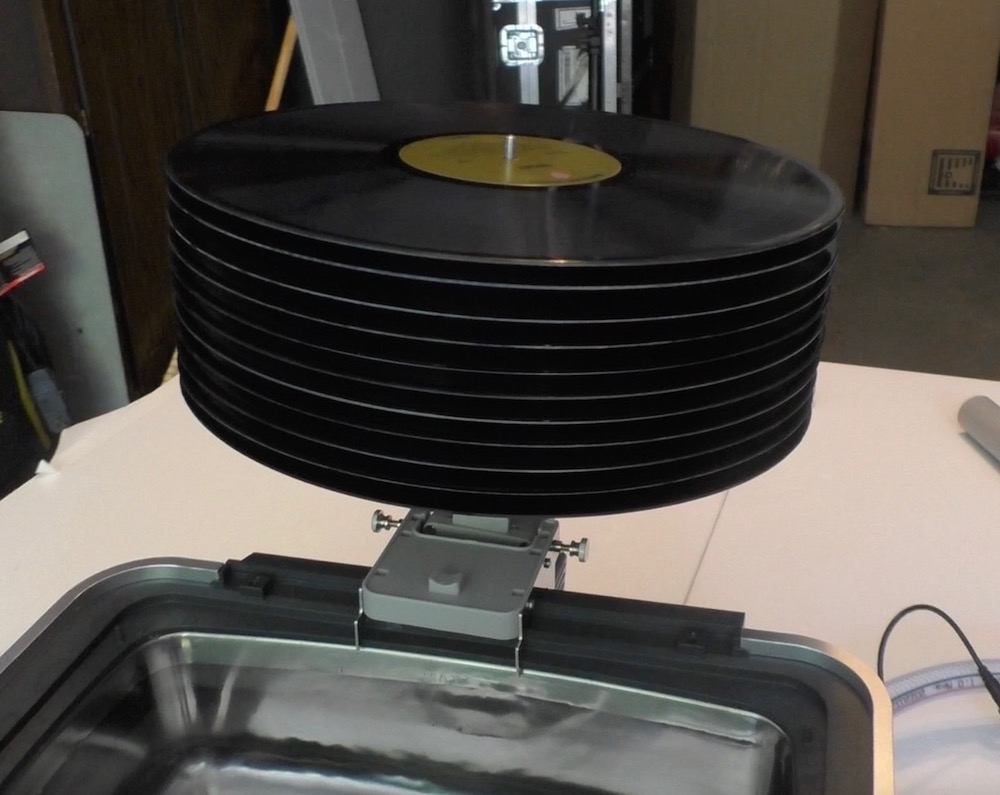

an ingeniously designed machine, but does a spit holding ten records in close proximity to one another help or hinder cavitation?

The iSonic CS 6.1-PRO is an ingeniously designed, relatively compact 1.55 gallon capacity cavitation-based $999 record cleaning machine capable of rotating up to ten 12" or 7" large hole 45rpm records in a stainless steel tank for up to fifteen minutes after which you drain the distilled water into a bucket and actuate a dual-speed high speed spinning mechanism that spins the records dry (a new reservoir with pump station will soon be available to make easier and more convenient, vat draining and refilling). In a relatively short time you should have up to ten cavitated clean, dry records. "Should" is the operative word.

CORRECTION: In the video and in the original description I mistakenly said there were two transducers in this machine. In fact, there is only one—it is the large circular outline at the bottom of the tank. The two square outlines are heaters. That there's but a single transducer better explains why the cavitation energy is so uneven across the width of the tank. I am sorry about this mistake but it doesn't change in any appreciable way the review itself.

The CS 6.1-PRO features one 80 watt, 48KHz cavitation transducer and a small disc 1µm in-water motorized filter. In addition to showing the machine in action and how it works this review attempts to determine whether effective cavitation is possible when ten records in close proximity to one another helps or hinders the cavitation process. Are the records being cavitated (cavitation is explained in the below video) or just spinning in a vat of water with added surfactant that results in surface-clean vinyl?

Up to ten records— 10" or 12" or 45rpm singles fit on a hinged "spit" separated by spacers that also act as label protecting water barriers. Once the loaded spit gets tipped down into the water and the unit is turned on, a heater set to one of three specified temperature settings activates, a de-gassing process begins and then the transducers begin the cavitation process to however long you've set the timer, up to 15 minutes.

The other end of the spit rests with a plastic "cradle" on the vat's opposite side. This hanging piece also holds the water filter that presses against the vat side wall to keep it clear of the spinning records.

Once cavitation finishes, and after turning off the motor, removing the in-water filter and draining the water into a clean bucket, the drying process commences by sliding the spit rotation switch in the opposite direction, which starts the motor spinning at an almost alarmingly high speed (upwards of 600 rpm) to cast water off of the records. A supplied shroud reduces but doesn't totally eliminate spray. Once that's finished, there's a beeping/chirping sound alerting you to the next part of the drying process that spins the spit at an even faster speed for up to eighteen minutes, at the end of which time, the records should be totally dry.

Once cavitation finishes, and after turning off the motor, removing the in-water filter and draining the water into a clean bucket, the drying process commences by sliding the spit rotation switch in the opposite direction, which starts the motor spinning at an almost alarmingly high speed (upwards of 600 rpm) to cast water off of the records. A supplied shroud reduces but doesn't totally eliminate spray. Once that's finished, there's a beeping/chirping sound alerting you to the next part of the drying process that spins the spit at an even faster speed for up to eighteen minutes, at the end of which time, the records should be totally dry.

Raise the spit on its hinge, remove the records and spacers and you've got ten clean, cavitated records. Or do you? That's what I sought to find out.

Setting up and using the machine is relatively easy once you understand how it all works and gets put together—there are many small, unfamiliar plastic parts. The instruction illustrations are small and the set-up guide is not particularly well-organized though I've seen worse!

Once you've loaded the records onto the vertically oriented 'spit' (as seen in the above photo) the assemblage, which rotates on two small plastic pins, gets carefully lowered into the vat. You then have to push forward the motorized spit assembly, securing a tab into an opening to lock it in place. It's further secured by tightening a pair of locking screws, one on either side of the motor housing.

After the entire cleaning process is complete you loosen the locking screws and pull back the motor housing, freeing the locking tab from the insert molded into the frame that hangs from the side of the vat. That allows you to again raise the spit to its vertical position so you can remove the cleaned and dried records. It's a tight fit that to free up requires a bit of side to side wiggling. One time it was particularly difficult to free up and I broke one of the plastic hinge pins. Apologies to iSonic, but it was so tight the alternative was to push and pry it free using a screw driver or chisel and that seemed like a worse choice.

iSonic once supplied a blue liquid surfactant/cleaner, but it produced too much foam so now the company includes a bottle of a lower foaming yellow fluid. The liquid's chemical make-up according to iSonic is: "alcohols, c12-16, ethoxylated >5EO, Dodecyldimethylamine oxide, Alkylamineoxides, oxirane, methyl-, polymer with oxirane.

If you look up some of these ingredients you'll find they are surfactants and emuslifiers. For instance Alkylamine oxide "... is an ingredient that can be found in shampoos and body washes. It is a cleaning agent that works with the other formula ingredients to break up and remove the soil." "Oxirane" is another name for ethylene oxide. According to the EPA:

"ethylene oxide is carcinogenic to humans by the inhalation route of exposure. Evidence in humans indicates that exposure to ethylene oxide increases the risk of lymphoid cancer and, for females, breast cancer".

So if you use this yellow liquid as a surfactant in the cavitation record cleaning process, don't breathe it in, and be sure to have good ventilation! And of course wash your hands.

That said, my experience with the KLAudio KD-CLN-LP200T cavitation-based cleaning machine tells me that no surfactant is required to produce sparkling-clean, finger-print free records, so why does iSonic (among others) recommend a surfactant?

I used the recommended amount of yellow fluid on ten not important records and stopped the drying cycle midway. When I removed the records from the spit I found they were coated with a not quite dry greasy film. You do rinse after using a body wash, don't you? My suggestion for using this yellow surfactant is to do what the shampoo instructions suggest: "rinse and repeat". In other words, drain the surfactant contaminated water, fill the vat with plain distilled water and give the records a rinse and dry. Otherwise you are sure to leave a dried surfactant coating on your records.

When I reviewed the KL Audio machine I gave it the "aluminum foil" test and it passed that by leaving the desired even pitting on the foil, indicating even-energy cavitation. Even without the test, it's obvious that the KL machine works as promised, leaving both a shiny record surface and a process that often results in the removal of long standing pops and clicks.

I realize that using the resources of a competing company (Kirmuss Audio) to test another company's machine raises some interesting ethical questions, but in the case of the KL Audio machine, the foil disc demonstrated the KL machine's cavitation efficacy. When I did the same test in the Audio Desk PRO, it proved that the Audio Desk is not a cavitation based machine, though, leaving aside it's long standing reliability issues, it is a very effective non-cavitation based cleaning machine—one that pioneered the "vat-type" record cleaning process.

To clarify another point: the Kirmuss machine passes the aluminum disc test and delivers even pitting across the entire surface of the disc, much as the KL Audio machine does. One additional point: iSonic does not manufacture Kirmuss's machine, or in fact their own. iSonic's machine is manufactured by Codyson Shenzhen as is Kirmuss's. Anyone can buy a stock machine from Codyson on its website. Kirmuss's machines are modified to his specs at his own factory (Anderson-Kirmuss-iNTELLI SmartBattery®).

In the video below you can watch how the machine operates followed by cavitation tests on the empty, water filled vat (there's definitely a high level of cavitation, though not evenly dispersed throughout the tank, and there are pockets of intense energy) and then in the vat with ten records on the spit, where, based on the meter readings, there's very little evidence of cavitation.

Finally, I put eight foil "records" on the spit and as with the KL test, gave it a single revolution in the cavitation bath. As you'll see, there's very little evidence of cavitation, and where there is cavitation on a few records, it's not evenly distributed and there are places where it appears to be extremely intense. In one case the pulsing heard in the audio may indicate to you "de-gassing" and not normal cavitation but the results were similar in the earlier tests so I just left the video "as-is".

While you watch the drying process you may be concerned by the action's "violence". You'll hear what sounds like rubbing, though I couldn't find the source nor did I see evidence on the record edges. I was particularly worried about whether the torque produced by the ultra-high speed spinning might slightly enlarge the spindle holes, especially if you've not tightly secured the stack of records on the spindle and any or all of the records are sufficiently free to bounce on the spit.

Conclusion

As you'll see in the video, the iSonic CS 6.1 PRO is definitely capable of washing and drying up to ten records in a single approximately 1/2 hour cycle. The records do come out clean and for the most part dry but they haven't been cavitated. If you choose to use the surfactant, you're best off following up with a second rinse and dry cycle (can be shorter) using plain distilled water to remove dried on surfactant.

Based on the foil test, and really, based on common sense, I don't see how a pair of cavitation transducers can work effectively between ten tightly spaced records spinning in a 1.5 gallon vat. I suspect two records, sufficiently spaced apart from one another would receive the benefits of cavitation, but I chose to review the product as it's intended to be used, with ten records on the spit. Based on the evidence, CS 6.1 owners who think they are caveating their records clean are most likely mistaken.

Interestingly if you go to the company's website finding the record cleaning machine will be difficult. It's not in what the company specializes—which is mostly for eyeglass cleaning, jewelry, etc. —even devices for accelerating alcoholic beverages (this one looks alarmingly similar to the original Kirmuss prototype machine, which I use.

The current Kirmuss machine looks like this:

The current Kirmuss machine looks like this:

if you search further for vinyl record cleaning machines, you'll find a few, but not this one. It's not clear who formulated the vinyl record cleaning fluids iSonic sells or how they differ from ones sold for jewelry cleaning. The 6.1's accessories are listed but not the 6.1 itself. However, a separate search for this particular model did pull it up on the company's website

My conclusion is that the ten records on the spit process can produce clean, dry records, much like the Audio Desk does a single record, but this machine costs 1/4 of that machine's price and it doesn't require costly rollers or equally costly bottles of surfactant concentrate. However, neither are effective cavitation devices, though the iSonic has that possibility when used with far fewer than ten records.

Cynics may conclude that the iSonic is a costly version of the starting at $79 Spin Clean but that would be cynical! As a non-cynic, I'd also conclude that faced with large-batch record cleaning chores (like, if you are a used record dealer), the iSonic starts to sound attractive and not all that costly for accomplishing that, though because of the potential "spray" even with the shroud in place, it shouldn't be used in close proximity to a costly audio system and is best used where the possible spray doesn't reach anything important.

Specifications

Specifications

Measurement | Metric | Imperial |

|---|---|---|

Tank Cap. | 6 L | 1.55 Gal. |

Tank Size | 31.1x17.2x11.6 cm | 12.2"x6.8"x4.6" |

Max. Level | 5 L | 1.3 Gal. |

Freq. | 48,000 Hz | 48,000 Hz |

Voltage | 220~240 V | 100~120 V |

Power | 80 + 160(heater) W | 80 + 160(heater) W |

Unit Size | 37.0x29.0x20.5 cm | 14.6"x11.4"x8.0" |

Manufacturer Information

Codyson Shenzhen, for Isonic Inc.

Phone: (847) 850-0404

Email: info@isonicinc.com

Address: 2243 S. Throop St.

Chicago, IL 60608

.png)