The Cryogenic Chronicles, Part 1

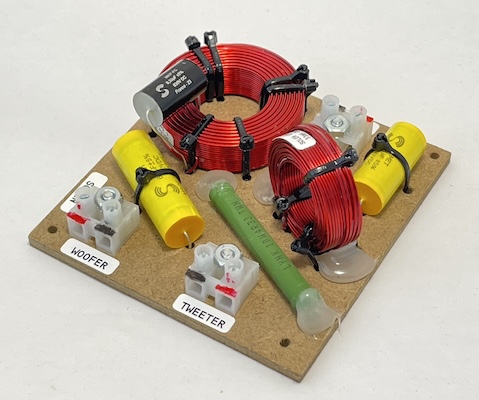

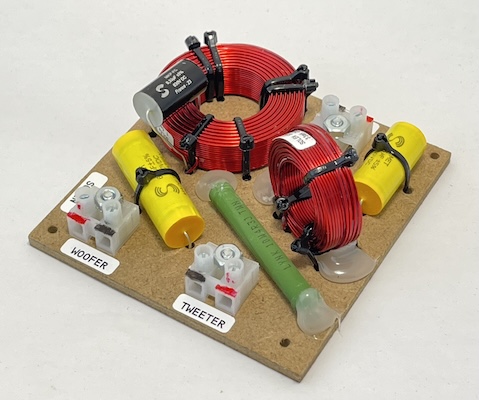

Loudspeaker Crossover "Cryo processing" subjected to rigorous testing

I am working on a major loudspeaker-design project. A floorstanding 3-way (not the speaker pictured, which is a pair of late 1990's era Ed Meitner designed Meliors). The Business Model is to deliver the sound quality of a $40,000/pair loudspeaker, but charge only $30,000/pair. Of course, in the Bill of Materials, I included both deluxe crossover parts, and the cryo processing of the completed crossovers. I was told that neither was necessary, but based on previous cryo experiences I had other ideas.

This not being “Mah first Rodeo,” I decided I had to devise a transparent and repeatable demonstration of the value of cryo’ed crossovers. I approached my friend at Solen Electronique in Montréal, and he was up for it.

If you are not familiar with Solen, I urge you to check out their website. Solen is not just about capacitors, inductors, and resistors! They sell all kinds of audio gear, and are especially strong in loudspeaker kits.

Before getting to the speaker and experiment designs here's a bit of my cryo experience:

Ed Meitner is a Larger-Than-Life figure in audio-engineering history. Born and trained in Engineering in Austria, he emigrated to Canada in 1969. By 1972, he was at Olive Electrodynamics, designing recording-studio consoles. In their recording consoles, Olive pioneered Voltage Controlled Amplifier (VCA) controls, as well as logic-switching circuits. Ed then moved on to the electronic test-equipment industry, and then on to the high end of the consumer-audio industry, as Chief Engineer of Museatex Audio.

Meitner designed in just about every category of Consumer Audio—from turntables and FM tuners, to digital gear and amplifiers and loudspeakers. In the mid 1990s, Museatex was famous for its non-electrostatic, dynamic panel loudspeaker, the Melior, which was a cover story for Audio magazine. (The basic technology was invented by Paul Burton, for Highwood Audio. Meitner was in charge of turning the concept into a commercial product.)

The Melior’s design was distinctive, to say the least. The plastic-film panel was under tension. Centered on its rear surface, there was a single voice coil. So... no conventional crossover. The complementary magnet structure was supported by a plastic X-frame and latticework that also served as an acoustic semi-baffle, to contour the back wave. The whole was covered in a dark gray fabric “sock,” at the bottom of which there was a high-gloss hardwood supporting element or pedestal.

The operating principle of the Melior panel loudspeaker was that the single central voice coil’s excursions would “crack the whip” of the tensioned panel, so that sound waves would then propagate at right angles to the surface of the panel. Furthermore, like “ripples in a pond,” the original impulse upon the panel would spread out in all directions.

That’s why Museatex called the Melior a “Single Point” loudspeaker—the high-frequency and low-frequency wave launches were concentric: “Cool!” I thought. Museatex was accomplishing by, for lack of a better word, mechanical means, what QUAD’s ESL-63 electrostatic loudspeaker accomplished by electronic delay lines powering concentric stators.

One of my career highlights was arranging for violinist Arturo Delmoni to play a sort-of “Music Minus One” demonstration of the Melior One loudspeakers at a Chicago Summer-CES “sit-down, tablecloth” luncheon thrown by Museatex. To my knowledge, that was the last-ever Summer CES.

It seemed that “everyone who was anyone” in audio journalism was there (except “HP;” and, honestly, I did not mind his absence at all). Julian Hirsch was there—I asked him to autograph my program booklet. Michael Fremer was there. (Let me know if you have not heard my story concerning the two of them, as they stood in line waiting to get in for lunch.) Frank Doris was there, too.

Earlier, back in Coventry, Rhode Island, in a tiny little rock-and-roll recording studio near scenic Lake Mishnock, I had recorded—in mono—and for good reason, that; Arturo, playing one solo part of J.S. Bach’s Concerto for Two Violins in d. I had been delighted to find a vintage RCA 44BX ribbon microphone in that studio’s mic locker, and that was what we used.

The pre-WWII RCA 44 radio-broadcast microphone (after it was later discontinued by RCA) was the “Mule” that David Hancock and Charles Fisher modified and hot-rodded for their microphone, the Cambridge Audio C35. In view of the enthusiastic reception the recorded violin sound on Songs My Mother Taught Me had received, I was delighted to find a very similar microphone. My foremost thought being, a ribbon microphone is more likely to commit audio Sins of Omission, rather than Sins of Commission. (Subtractive errors, rather than additive errors.)

Museatex’s Journalists’ Lunch took place in the Everest Room restaurant, atop the building that houses the Chicago Board of Trade. Ritzy! Arturo and I arrived early. Upon meeting Ed Meitner in the flesh for the first time, I exclaimed, “Ed, just ask anyone! I always say that if there are five Genius-Level Innovators in audio engineering, you are at least three of them!”

Without skipping a beat, Ed gave a courtly little nod, and replied, “We are very pleased to meet you!”

In addition to designing lots of consumer playback gear, Meitner’s significant engineering accomplishments include a Jitter Measurement System (the “LIM Detector”), and the “Very Fast, 1-Bit” digital-audio recording and playback protocol. Meitner’s 1-Bit system later became the (so to speak) backbone of Sony’s “Direct-Stream Digital” (DSD) system, which is how the hi-res data is encoded on an SACD disc.

There’s an irony there: Meitner’s original design goal had been to extend the battery life of portable, battery-powered digital devices. Does anyone remember the Discman?

Anyway, back to the Summer CES lunch. Two Melior One panel loudspeakers had been set up, standing rather distantly apart (which was one of the reasons I had recorded Arturo in mono), on a slightly higher (three stair steps) level of the restaurant than the 40 or so lunch guests were seated on.

Ed hit “Play” on the CD transport, the loudspeakers began playing the second-violin part of the slow movement of the Bach Double concerto, and, at the right moment, the live Arturo joined in, playing the first-violin part. It did not suck!

The audience was very, very attentive. Even the waitstaff stood and listened. At the back of the room I quietly moved from a center position to an off-center position. I was hugely relieved that the timbre of the playback did not change radically as I moved off-center.

Well, Bach’s Two-Violin Concerto’s slow movement is only 50 measures in 12/8, Largo, ma non tanto time. Therefore, after about seven minutes of auditory bliss, the demonstration was over.

My relief knew no bounds. I was especially impressed by the measure-and-a-half on the last page of the score where the second violin (the pre-recorded part) plays a phrase on its own, making it very easy to listen to the recorded sound from the speakers only, and then with the added live-violin sound.

The lunch wrapped up, and I chatted with Ed as I helped him, so to speak, strike the set. Ed told me that I really should be cryogenically processing Arturo’s CDs. Hunh?

I was a bit of an amateur woodworker, and I had heard that some woodworkers claimed that if you had your router bits or whatever cryogenically processed, you did not have to have them re-sharpened as often. Well, that sort-of made sense to me.

Heat-tempering is part of the making of tool steel. So, why couldn’t cryogenic processing, considered as “Cold Tempering,” also make for better outcomes? I guessed that the mechanism was that the cryo created a better alignment of all the sub-microscopic crystalline lattices, resulting in a harder and more durable product.

BTW, if anyone is tempted to think that the above is “Pure Wish Fulfillment, Masquerading as Bafflegab,” there are scientific papers on cryo and tool steel, dealing with the changed ratios of Austenitic versus Martensitic crystals.

Even more to the point, many (and perhaps most) NASCAR teams use cryogenic processing on critical high-stress components, such as connecting rods and camshafts. I assure you: Nobody is playing Jedi Mind Tricks on NASCAR Chief Mechanics. They are going by their own results.

OK. But: How could something that improves the crystalline structure of tool steel enhance the performance of a Digital Audio Compact Disc, nearly all of which were injection-molded polycarbonate plastic?

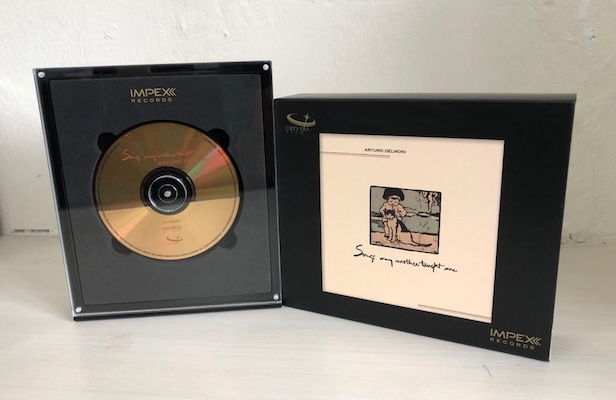

The few exceptions being the hyper-expensive Polyolefin plastic CDs, which were in vogue for a few months, it seemed. I inquired; the pressing price they quoted me was about $5 per CD, not counting shipping from Japan. Um, that was versus the 65 cents (per naked disc, no label printing, no paper parts, no jewel box, no shipping) that I was then paying to the folks in Indiana. More recently, there have been optical-glass CDs. The limited-edition Songs My Mother Taught Me “Gold on Glass” CD had an MSRP of $1,200 each. That limited edition sold out quickly.

Ed shrugged off my doubts. He said something along the line of, “Trust me, it just works.” He later introduced me to the cryo processing company he used, which happened to be up the highway from me, in Massachusetts. I sent them a few copies of Arturo’s Water Lily CD of solo-violin music of Ysaÿe, Kreisler, and Bach.

The package containing the cryo’ed CDs arrived while my (then-) wife was not at home. She came back, dropped off some groceries in the kitchen, and then… from another room in the house, she incredulously asked, “WHAT did you do to Arturo?”

(By which she obviously meant, what had I done to the sound of Arturo’s violin? Which was a beyond-priceless J.B. Guadagnini, vintage 1780. That violin had been played by the Concertmaster of the string section of the epochal recordings that later made up the LP album, Charlie Parker With Strings. So, even before Arturo’s stewardship of it, it was one of the “Most Heard” violins in the world.)

She continued—from about 15 feet away from the archway entrance to the listening room: “It sounds like he’s playing a viola, in the fifth position.” Ouch. Well, that’s what I get for marrying another string player.

I think that she was indicating that she was hearing a significant difference in a familiar recording. Hmmm. My reaction had been the opposite. I thought that the violin sound from the cryo’ed CD was more natural and more coherent, with no extra energy in the treble.

All of which was very interesting. But, the economics of flailing around in the dying days of the “classical-music-on-physical-media, sold-at-retail-price, in-retail-stores” Business Model meant that cryo-processing entire spindles of naked CDs, at $150 a pop, wasn’t something that my resellers or customers were willing to pay extra for. Plus shipping forth and back. Especially after the retail mark-up on all of it.

I later had an over-press of about 50 JMR 24-kt.-Gold CDs of SMMTM. I threw them in with a bunch of cables I was having cryo’ed. I sold those CDs, onesie-twosie, on eBay. Doubtless, they were purchased more for the Gold aspect, than for the Cryo aspect.

I later read in the professional audio-replication journals that some people had studied the effect, and had concluded that what cryogenics did to polycarb CDs was that it changed the polycarbonate’s Modulus of Elasticity, conferring more self-damping, while at the same time lowering the Quality (“Q”) Factor of the disc’s mechanical resonances.

The reason those effects can reasonably be accepted as improving playback quality is that a “floppier” disc, with more self-damping, means that the CD transport’s Tracking and Focus servo systems will be working less hard, and less often.

That should result in better clocking, keeping in mind that, in the S/PDIF Compact Disc system, no separate Word Clock per se is transmitted. The clocking of digital words has to be inferred (or reconstructed) by reference to the zero-axis crossing points of the waveforms of the photocell’s output.

So, What About Crossovers?

At some point in there, I began designing and building S/PDIF digital cables, according to my own recipe. My design goals were to minimize the deleterious effects of internal reflections within the cable.

By which I mean, any impedance mis-match, no matter how small, between the characteristic impedance of the cable and the characteristic impedance of what it is plugged into, can result in a small part of the electromagnetic flux being reflected back where it came from, so to speak.

My theory being that such reflections are basically baked into the loaf. Therefore, the best we can do is to calculate the length of the S/PDIF cable so that the reflected energy arrives “back home” in a time frame where it will do the least harm to the timing of the Zero-Axis Crossing Points of the just-then-newly-launched signal. Because it is the Zero-Axis Crossing Points that determine clocking, and therefore the jitter content.

Wanting to minimize the impact of the mechanical and thermal stresses of the cable fabrication process, of course I had my digital cables cryo’ed. I immediately heard an improvement.

But you also must know that, one of these days, the Roman Catholic Church is going to get around to declaring me to be the Patron Saint of “Confirmation Bias” (there just might be a tiny pun, lurking there).

BTW, just a couple of weeks ago, I learned that, in 1958, the then-Pope declared Clare (or Clara), the companion of Francis of Assisi, to be the Patron Saint of… television. Ya caint make stuff like that up. Clare apparently saw… visions.

I sent one of my “Esperanto Audio” “Blue” S/PDIF cables to a friend who, back then, was one of the most famous mastering engineers in the world. He went so far as to set up a blind listening test session with the other mastering engineers on his staff. He ABX’ed; they listened “blind.”

He later reported back to me that his staff was not able to hear any differences between the S/PDIF cable he was already using, and my cable. I was ecstatic. I believe that the cable he was using cost about $3,000 for one meter. My cable (at that time) was (retail) $600 for one (non-negotiable) custom length that was longer than 1m. (I already anticipate what some of the responses will be… .)

Despite and still, fighting against cable brands with installed dealer bases, and which were supported with magazine advertising, really wore me out, and I quietly pulled back.

At that point, I got back into my previous hobby of designing small, affordable, high-performance, for lack of a better term, “Satellite Monitor” loudspeakers. My design partner and I got to a point we felt we had a worthy contender.

The Head of Sales for a legendary loudspeaker maker spent a couple of weeks with our pair of prototypes in his home, reporting back that our prototypes had nearly-perfect timbral balance, and (IIRC) “Spectral” (Ghostly) imaging. But, according to him, in the real world they were a total never-happen non-starter, because they were less than 80dB efficient.

My three-word response was, “Watts Is Cheap.” He was unsmiling.

The point being, before shipping our only pair of prototypes out to an Industry Big Guy, we had squandered the Baksheesh, Moolashe, Dinheiros or whatever, to have both crossovers cryogenically processed. Note well, because we had both crossovers processed together, we had to rely upon aural memory to make a comparison.

We were knocked out. Faster sound, lower noise floor, more detail, you name it.

But that was a non-repeatable, non-transportable experiment.

So, John! What do you have for us, in Anno Domini MMXXV?

Glad you asked; thanks!

We decided to use Solen’s new, ultra-affordable “Mura 5B” kit as a test subject. The Mura 5B is a 2-way "Bookshelf" design with SB Acoustics drivers: a 5.5-inch fiber cone woofer-mid, and a 19mm textile dome tweeter. One thing that made this kit attractive to me is that its crossover is of the Old-School “Breadboard” type (and not a PCB), which means hand-soldered, point-to-point hard wiring.

The other things that made the Mura attractive to me are that Solen also sells a CKD (Completely Knocked Down) “Flatpack” set of boards to glue up into cabinets, and, the “Crazy Eddie” pricing, of course. How cheap? How about kit of parts plus the CKD cabinets, under USD$250 a pair (plus shipping). I’d call that Royal Canadian Mounted Cheap! And, if trekking out to Home Depot to buy woodworking clamps doesn’t work for you, I am confident that if you ask nicely, Solen will quote you a price on a pair of assembled and tested loudspeakers.

How will this work? Glad you asked.

1. Solen will wire up two Mura 5B crossovers. One of them will have an inconspicuous little Sharpie mark on it, perhaps a “+” sign. I will ask them to cut and attach all the internal hookup wires, so those will get cryo’ed as well.

Note, I have asked Solen to measure and listen to both crossovers before shipping one out, to make sure they measure and sound the same.

2. Solen will then ship that single marked crossover and wires to Performance Metal, a precision metallurgical-finishing company in Anderson, Indiana. The kind folks at Performance Metal agreed to cryo-process that crossover board twice, with a resting interval in between, at no charge. Thanks, guys. BTW, their charges for small items are very reasonable. Cryo CDs, anyone? Performance Metal will then send that 2X cryo’ed crossover board back to Solen.

3. Solen then will glue up the cabinets, assign serial numbers to each, assemble and test the loudspeakers, and then do a comparative listen.

4. BUT WAIT! THERE’S MORE! In order to remove Confirmation Bias as an active factor, Solen will then ship both completed loudspeakers to Michael Fremer, not telling him which is which. Michael will then let us all know.

How about them apples?

I await your comments!

PS: In an effort to reach a wider audience, Museatex released a "Hybrid" loudspeaker with a small-ish (at least compared to the original Melior One) planar-dynamic panel, atop a conventional cone woofer in a box. Sad to relate, they sent a not-fully-worked, mos def' "Not Ready for Prime Time" review pair to Stereophile, and the resulting review is... painful to read. If you go in for such things. "The realization came almost instantly that the Hybrid 6 just wasn't doing it for me" is just the beginning.

.png)