Two Must See Seminars at Florida International Audio Expo 2023

Finally! cavitation explained clearly and concisely and the 7 targets of proper cartridge alignment

What exactly is "cavitation" as applied to record cleaning? None of the novelty videos on YouTube explain what it is and most of them make recommendations that clearly indicate the advocates have no idea what they are talking about! In fact, many of the "cavitation" machines do not actually cavitate.

What are the 7 alignment targets necessary to hit in order to properly align a cartridge? And what are the benefits of proper alignment in addition to better sonic performance?

These two seminars are not advertorials though of course products are involved. I've spent years mercilessly playing the skeptic to Charles Kirmuss's claims about cavitation-based record cleaning and preservation/restoration and his methodology. I once published a story and video provocatively titled "If Kirmuss is Right About Record Cleaning, is Everyone Else Wrong?"

I've also watched his seminars evolve from Ron Popeil-like sales pitch to one that makes complete sense, beginning with an explanation of what cavitation is that I've confirmed elsewhere and why some other machines do not qualify as true cavitation devices. My skepticism has forced Mr. Kirmuss to invest heavily in microscopes and measurement devices to prove his claims and I'm glad I pushed him and that he accepted the challenge.

The timing could not be better because shortly I'll post a video here that will review and demonstrate four vat-type record cleaning machines and put to the test Kirmuss's claims about his and others. One thing I've learned is that people advocating the use of surfactants and fluids like Turgicleen with cavitation, do not know what they are talking about. Such products do nothing to aid true cavitation. They may or may not be useful in other record cleaning methodology.

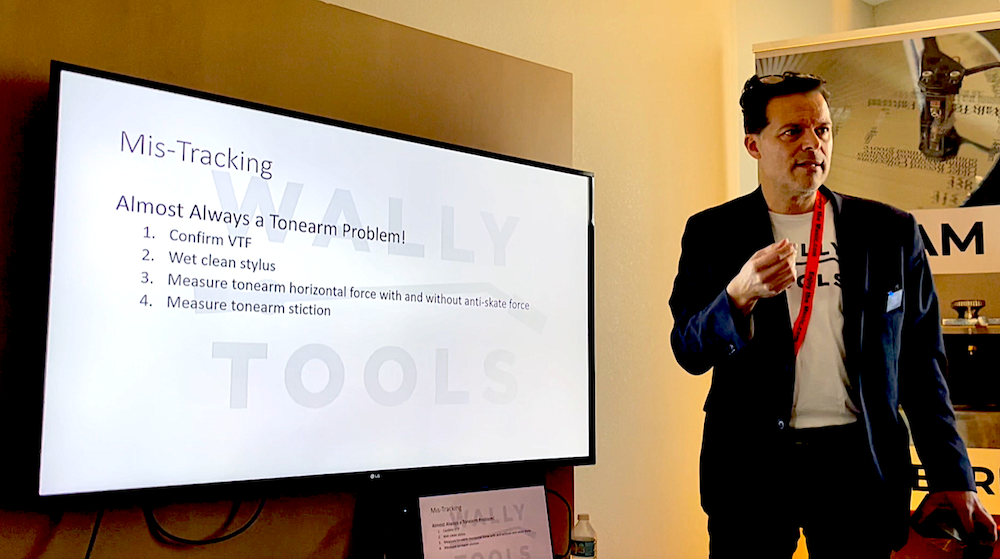

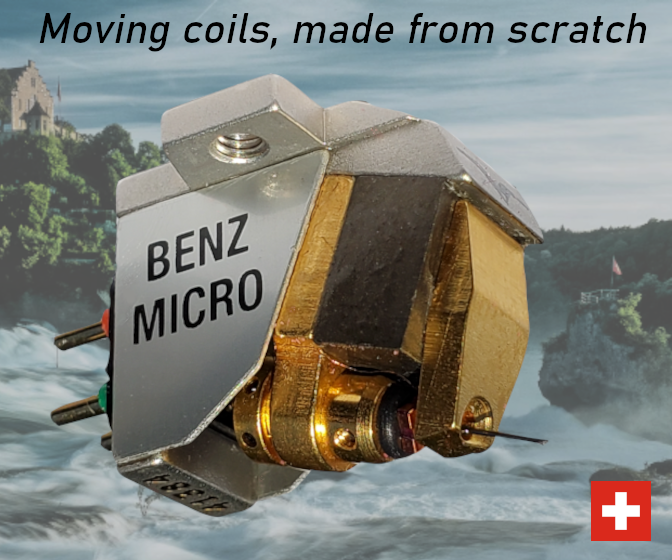

WAM Engineering's J.R. Boisclair, who manufactures and distributes WallyTool turntable set up tools does a fact-pact seminar explain the 7 set up target points and why they are important for proper turntable set up. I've been using and recommending WallyTools for decades and watched J.R. improve the products after he took over for the late Wally Malewicz.

His seminar is not product-based, but rather fact and information based. He's examined hundreds of costly cartridges and found shockingly poor quality control in many samples. His inspection service, which costs approximately $500 is money well spent if you've invested 10X that much on a cartridge. If it's only slightly "off" he can provide a fix that will produce top performance. if it's way off, he can offer proof to justify your returning your purchase for a properly manufactured sample.

After editing this video and watching it a second time, I feel fully confident in claiming that this video is among, if not the most important and useful video you will find on YouTube— if you are serious about vinyl playback and proper record care.

.png)